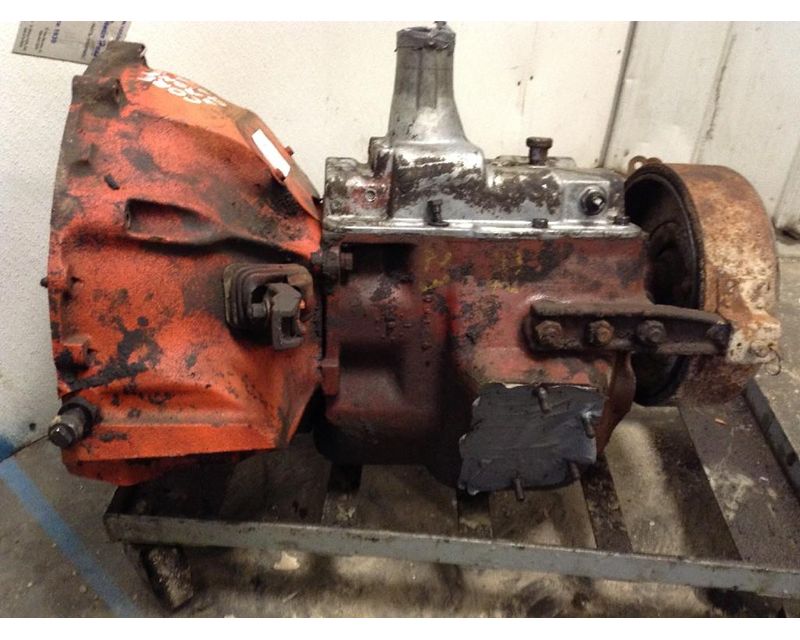

New Process 542 Manual Transmission

Need New Process/New Venture 542 Transmission Assy Parts? Check out 10 New Process/New Venture 542 Transmission Assy Parts for sale. We help you find the heavy duty truck parts that you need. Search Results for New Process Transmission Assembly on HeavyTruckParts.Net. Easily find what you need from 1,618,594 parts available.

Login or Register

The Novak Guide to the

The 435 is an excellent, heavy-duty truck transmission designed and used in ½, 3/4 and 1+ ton trucks. It is a well-built transmission and remains easy to locate and generally inexpensive to buy and maintain. The strength, relatively short size and the gearing of the transmission make it a good choice for a variety of situations.

The NP435 was made by New Process Gear from 1962 thru 1997. They are found primarily in Ford trucks from 1966 to 1992 and Dodge trucks from 1962 to 1993. They also had limited distribution in GM & Chevrolet trucks from 1968-1972. They are also found in some International Harvester and industrial applications.

Identification

This transmission is 10.8' long and features an aluminum top cover that is retained by eight bolts. The NP435 case is of cast iron.

The Ford NP435 has a 1-1/16' diameter, ten spline input shaft that has a stick-out of 6-1/2' from the front face of the transmission. The pilot tip of the transmission measures ~17mm. The front bearing retainer flange measures 4.85' and the bearing retainer tube is 1.43' in diameter. The front bolt pattern is the symmetrical Ford 'butterfly' pattern; roughly 8-1/2' wide by 6-5/16' tall.

The early Dodge NP435 up through 1968 had a 10 spline, 1' OD input shaft. Dodge units after 1968 have a 23 spline input shaft with an 8-3/8' stickout. The Dodge NP435 featured two different styles of front input shaft & bearing retainer. The earlier and less common style (from 1962-) generally used a deep ball roller bearing input. These earlier units are not compatible with our conversion assemblies. While ball bearing front versions still persisted in some applications, they were rarer after 1969. The more common and later style featured a tapered roller bearing and cup assembly. These later versions are compatible with all of our adapter assemblies.

The GM / Chevrolet NP435 has a 10 spline input shaft with a 6-1/2' stick-out length. This version was only available with the roller style input bearing instead of the later and more common tapered bearing design. None of the GM NP435's are compatible with our adapter assemblies.

The shifting pattern for all of the 435's is in the standard 'H' pattern with reverse gear being to the right side, and down.

| 1st | 2nd | 3rd | 4th (direct) | Rev. | |

| NP435A (Dodge, GM) | 4.56 | 2.28 | 1.31 | 1.00 | 5.64 |

| NP435L (Ford, Dodge, GM) | 6.68 | 3.34 | 1.66 | 1.0 | 8.26 |

| NP435D (GM) | 4.90 | 2.29 | 1.19 | 1.00 | 6.06 |

| NP435E (Ford) | 6.68 | 3.34 | 1.74 | 1.00 | 8.26 |

There may be no tagging nor proper tag interpretation to know which version of the 435 one may have. However, if trying to identify by the third gear ratio, one should count the mainshaft third gear teeth; 23 teeth for 1.66:1, 24 teeth for 1.74:1 and 25 teeth for 1.31:1.

Note that we have encountered a version of the NP435 with a helically steeper cut 2nd gear, which does not interchange with the overwhelming majority of 2nd gears, nor mesh with the corresponding cluster shaft gear. The tooth count and gear ratio are the same.

Features

The NP435 is a top loaded, top shifting truck style transmission. The NP435 enjoys a very low compound gear at 6.68:1 and as such it is a popular choice for those wanting a very low crawling gear. Note that some Dodge versions of this transmission offered a taller first gear of 4.56-to-1.

The NP435 features a power-take-off (PTO) port on the passenger side of the case.

Transfer Case Adaptability

This transmission makes an excellent conversion transmission due to its adaptability into most Jeeps. Both 2wd and 4wd versions of the NP435 can be used equally well, and there are no inherent advantages to either one once you have installed our adapter assembly.

The Ford and Dodge 435 can be adapted to the popular Jeep (and many IH) transfer cases, including the:

Dana 18, 1941-1971

Dana 20, 1962-1979

Dana 300, 1980-1986

2wd & divorced 4wd & Dana 21 adapter pattern

4wd (married) adapter pattern

There are two-wheel-drive and four-wheel-drive models; the critical difference being in the bolt pattern of the rear adapter housing or tail housing. Ford 4wd trucks with the remote (commonly termed 'divorced') mounted transfer cases actually have the two-wheel-drive bolt pattern on the rear face and the installer should make this distinction when ordering the adapter assembly. Of note, the NP435's as married to the Dana 21 (single-speed transfer case) featured the 2wd pattern.

The Chevy / GM versions of the NP435 is different in its design, fairly rare and we do not support these adaptations. The installer can consider the SM465for as a very good alternative.

Engine Compatibility and Adaptability

The front face bolt pattern of the Ford NP435. This particular version has been cast without the extra, undrilled ears that are useful when adapting to a GM bellhousing.

Dodge & Ford

As the reader will conclude, the Dodge NP435 will marry directly to a Dodge style bellhousing. Likewise for the Ford NP435 and its bellhousing compatibilities.

AMC Jeep

The Ford NP435 is also an excellent candidate for AMC Jeep bellhousings made from 1976 to 1986 that were married to the T150, T18 and T176 transmissions, or otherwise have an available bellhousing bolt pattern of 8-1/2' wide by 6-5/16' tall. They are readily compatible with these engines and bellhousings, and need only a custom pilot bushing. For more details, see Adapting Ford Transmissions to AMC Bellhousings for details.

GM

Many of the Ford NP435's have two extra undrilled ears cast into the front face of the transmission case. This is important if you intend to run it behind a GM bellhousing. The transmission having these extra undrilled ears will greatly simplify its use with GM engines. For more details, see Adapting Ford Transmissions to GM Bellhousings.

Rebuilding the NP435

Improperly flat-towing (pulling a vehicle not under its own power) any vehicle with the NP435 transmission can cause the very prompt destruction of third gear bore and its mainshaft journal due to insufficient oiling.

If you must flat-tow, and have a transfer case, you may set it in full neutral and place the NP435 in any gear to prevent mainshaft spin. However, note that many transfer cases themselves do not allow for flat towing.

Preferably, you may wish to disconnect the rear drive shaft. Rear axle lockout hubs may be a worthwhile addition for this reason.

We have seen and heard of a few incidents of this over the years, the worst of which producing a complete friction welding of third gear to its mainshaft.

This is one of the only quirks of the 435, and easily avoidable.

The NP435 is relatively simple to rebuild. Many shadetree mechanics do very outstanding rebuilds if they have access to a press, snap ring pliers and bearing pullers. Many choose to do a full rebuild during the adaptation process, and our instruction guides feature all the details, diagrams, pics and tricks required to do professional level work.

When filling your 435 with gear oil, we recommend that you select a conventional mineral oil or a para-synthetic in lieu of a full synthetic oil. Properly assembled manual gearboxes do not have the thermal strains seen by combustion engines or hypoid gears. Synthetic fluid in these gearboxes, while not harmful, is probably an economic waste.

Hypoid gear oil is sulphurized higher than transmission oil and can be mildly corrosive to the non-ferrous alloys used for synchros, bushings and thrust washers in these transmissions.

An 80W-90, API-GL5 or MT-1 rated fluid is very good. Some claim faster shifts from using a 50W engine oil in their transmission and we do not consider this to be contraindicated unless you operate your vehicle in a very warm environment.

L x W x H:4,6 m x 1,9 m x 2,8 mEmpty weight:285-305 kgMTOW:450-600 kgEngine:Rotax 915 ISTakeoff distance. Gyrocopter plans specifications.

| Industry | Vehicle Transmissions |

|---|---|

| Fate | Dissolved |

| Predecessor | |

| Founded | 1990; 30 years ago |

| Founder | |

| Defunct | August 20, 2012 |

| Headquarters | , |

| Parent | Magna Powertrain |

New Venture Gear, a division of Magna Powertrain, was an automobile and light trucktransmission company that was started in 1990 as the first ever joint venture between any of the Big Three US automakers. General Motors and Chrysler Corporation were the participants. Operation and management of Chrysler's New Process Gear Syracuse, New York, plant and GM's underutilized Muncie, Indiana, Hydramatic transmission plant were shifted to New Venture Gear Company.[1]

- 1Founding partner plant histories

- 2New Venture Gear transmissions and transfer cases

Founding partner plant histories[edit]

Hydramatic Muncie[edit]

In 1902 Thomas W. Warner formed the Warner Gear Company in Muncie, Indiana, to manufacture automobile parts, steering, and transmission gears. In 1919, General Motors purchased the T.W. Warner Company, including its land and buildings. In 1920 GM reopened the plant under the name Muncie Products to manufacture transmissions and steering gear for their Oakland, Pontiac, Oldsmobile, Chevrolet, and GMC-Truck divisions. In 1932 GM closed the Muncie Products plant and consolidated operations to other divisions in response to the failing economy. The Chevrolet division re-opened the plant in 1935 to build car and truck transmissions. World War II halted non military vehicle production and the plant was converted to serve the US military demand until the war ended. The 1950s and 60s saw expansion and growth. In the 1970s and 80s GM swapped the plant to many different GM divisions ending with Detroit Diesel Allison in 1984 and GM Hydramatic in 1986.[2] In 1990 Hydramatic Muncie plant became part of the GM-Chrysler New Venture Gear. In February 2002 General Motors sold its minority 36% stake in the New Venture Gear company to DaimlerChrysler and the Muncie Transmission plant reverted to GM control. GM changed the plant name to 'Manual Transmissions Of Muncie'. The T.W. Warner Muncie plant closed in mid-2006 after a century of operation and the property was turned over to Delaware County Indiana. The GM Muncie Transmission plant was demolished soon after turnover to the county.[3]

New Process Gear[edit]

In 1888 Thomas W. Meachem founded the New Process Rawhide Company in Baldwinsville, New York. In the late 1890s New Process Rawhide moved operations to Syracuse after a fire. In 1913 Thomas W. Meachem reorganized New Process Rawhide with one of his partners, Artemus Vosburgh. The company was renamed New Process Gear to reflect the new corporate direction. In 1954, after a succession of owners including Willys-Overland,[4] New Process Gear became a subsidiary of Chrysler Corporation.[5] In 1990, under a new joint GM–Chrysler venture, New Process Gear was renamed 'New Process Gear Division' of New Venture Gear. In 1998 Daimler Benz merged with Chrysler to form Daimler Chrysler. In 2002 Daimler Chrysler bought the entire 36% minority stake in New Venture Gear from GM while retaining ownership of the Syracuse New Process facilities. In 2004 Canada based Magna International purchased 80% of New Venture Gear from Daimler Chrysler. In 2007 Magna purchased the remaining 20% interest. The New Process gear plant remained property of Daimler Chrysler. Chrysler then leased the facilities to Magna.[6] This lease arrangement made it difficult to compete with the European manufacturing operation Magna directly purchased located in Roitzsch Germany.[7] A downturn in Jeep demand combined with DaimlerChrysler not replacing the Dodge Neon sharply curtailed demand for the Syracuse New Process Gear plant production. In 2009 design and engineering services were moved to Troy, Michigan, and Magna International announced its intent to close the Syracuse plant. The Syracuse New Process Gear plant planned closure in November 2011 was pushed out till first quarter of 2012.[8] After 124 years in operation, on Thursday, August 24, 2012, New Process Gear ended production and closed their doors for the last time.[9]

Xforce keygen 2010 32 bit & 64 bit, xforce for autocad 2010 full, how to active key autocad 2010. One Response to xforce keygen 2010 32 bit & 64 bit. Fast same day cash loans no credit check says: June 15, 2019 at 5:33 pm. Thankyou for this practical opinion on what is usually a forgotten topic. Is it okay to link this with my group? 2012 crack key download - 32bit version activation Patch 1 month ago 0. Is the 4th generation better than the 5th generation Autocad 2018 crack is out now. Download AutoCAD 2018 32bit & 64bit with keygen torrent link and direct download link. Crack AutoCAD 2018 using x-force keygen by Ingegneria e intrattenimento.the 2018 trial version. AutoCAD x-force KeyGen Crack Full Home. Fashion; AutoCAD 2010 Full Crack Download AutoCAD 2010. Xforce keygen provided is created by expert coder who have experience of many years in creating hacks, cracks and keygens for different type of online and multiplayer games. This is the original & real serial key generator for xforce keygen Crack. 5 2011 autocad 2010 full version 64 bit Once at the activation screen Start XFORCE Keygen 32 64bits 7.Click on 28 Mei 2010 129B1 AutoCAD Map 3D 2010. 237B1 AutoCAD Civil 3D. 057B1 AutoCAD LT 2010. 185B1 AutoCAD Architecture 2010 program yang anda instal tadi dengan menggunakan keygen. 10 September 2014 12.23 Yonie Rio mengatakan X-force. Keygen x force autocad 2010.

New Venture Gear transmissions and transfer cases[edit]

The Muncie, Indiana, plant under New Venture Gear produced the NV4500, NV3500, and NV3550 light truck transmissions.

The Syracuse New Process Gear plant produced transfer cases for all of the 'Big Three' Ford, Chrysler, and General Motors. The NV 247 all-wheel drive transfer case, sold by Chrysler's Jeep division as the 'Quadra-Trac II', the manual transaxle for the Dodge Neon and PT Cruiser (T-350), and manual transaxles for European export Chrysler minivans (T-650 & 750) were the bulk of their last years of production.

Transfer case model nomenclature[edit]

| Manufacturer | Number of speeds/gears | Strength | Type |

|---|---|---|---|

| NP = New Process Gear NV = New Venture Gear | 1 = One speed (high range) 2 = Two speed (high and low range) | 1 (low) to 7 (high) | 1 = Part-time 4WD 2 = Full-time 4WD 3 = Electronic shift 4 = Not currently used 5 = Torsen-type differential 6 = Computer-controlled multi-plate wet clutch 7 = GeroDisc 8 = Not currently used 9 = Viscous coupling |

New Process Gear and New Venture Gear transfer cases[edit]

| Model | Full-Time High | High Lock | Low range | 2WD | Differential |

|---|---|---|---|---|---|

| 119 | Yes | No | No | No | Yes (Viscous) |

| 125 | Yes | No | No | No | Yes (Open) |

| 128 | Yes | No | No | Yes | Yes (Open) |

| 129 | Yes | No | No | Yes | Yes (Viscous) |

| 136 | |||||

| 147 | Yes | No | No | No (GeroDisc) | |

| 203 | Yes | Yes | 2.01:1 | No | Yes (Open) |

| 205 | No | Yes | 1.96:1 | Yes | No (Locked) |

| 207 | No | Yes | 2.61:1 | Yes | No (Locked) |

| 208 | No | Yes | 2.61:1 | Yes | No (Locked) |

| 219 | Yes | Yes | Yes | No | Yes (Viscous) |

| 228 | Yes | No | Yes | Yes | Yes (Open) |

| 229 | Yes | No | Yes | Yes | Yes (Viscous) |

| 231 | No | Yes | 2.72:1 | Yes | No (Locked) |

| 233 | No | Yes | 2.72:1 | Yes | |

| 236[10] | Yes | Yes | 2.72:1 | Yes | |

| 241 | No | Yes | 2.72:1 | Yes | No (Locked) |

| 241OR | No | Yes | 4.0:1 | Yes | No (Locked) |

| 242 | Yes | Yes | 2.72:1 | Yes | Yes (Open) |

| 243 | |||||

| 244 | Yes | Yes | 2.72:1 | No | Yes (Open) |

| 245 | Yes | No | 2.72:1 | No | Yes (Clutch) |

| 246 | Yes | Yes | 2.72:1 | Yes | |

| 247 | Yes | No | 2.72:1 | No | No (GeroDisc) |

| 249 | Yes | No (Pre 96), Yes (96+) | 2.72:1 | No | Yes (Viscous) |

| 261 | No | Yes | 2.72:1 | Yes | No (Locked) |

| 263 | No | Yes | 2.72:1 | Yes | |

| 271 | No | Yes | 2.72:1 | Yes | No (Locked) |

| 273 | No | Yes | 2.72:1 | Yes | No (Locked) |

Closure[edit]

- After 124 years in business, New Venture Gear started to close in the week of August 20, 2012, and was fully shut down by the end of the week.[11]

See also[edit]

References[edit]

- ^'COMPANY NEWS; Joint Venture Planned By G.M. and Chrysler - New York Times'. Nytimes.com. February 7, 1990. Retrieved May 9, 2013.

- ^'Muncie Chevrolet Plant Architectural Drawings, 1918–1920'(PDF). Bsu.edu. Retrieved March 7, 2017.

- ^'New Process Gear and New Venture Gear History'. Allpar.com. September 29, 2004. Retrieved May 9, 2013.

- ^'MoparWiki'. Moparstyle.com. Retrieved May 9, 2013.

- ^Central New York. 'Last day for 300 New Process Gear workers; here are three who've moved on'. syracuse.com. Retrieved May 9, 2013.

- ^'New Process Gear, Inc. Company Profile from Hoover's'. Hoovers.com. Retrieved May 9, 2013.

- ^'Magna Completes Purchase of New Venture Gear'. Geartechnology.com. December 22, 2003. Retrieved May 9, 2013.

- ^Dennis Nett / The Post-Standard. 'New Process Gear in DeWitt plans to remain open into next year'. syracuse.com. Retrieved May 9, 2013.

- ^Central New York. 'New Process Gear stops production this week after 124 years'. Syracuse.com. Retrieved May 9, 2013.

- ^'NP236 Transfer Case'. Midwest Transmission Zumbrota MN. 2010. Retrieved June 6, 2017.

- ^Hannagan, Charley (August 20, 2012). 'New Process Gear stops production this week after 124 years'. syracuse.com The Post-Standard. Advance Media New York. Retrieved June 6, 2017.

Further reading[edit]

- 'History of Magna International Inc'. Magna International. Archived from the original on November 11, 2010. Retrieved December 21, 2010.

- 'SAE TopTec: Innovations in Four Wheel Drive/All Wheel Drive Systems'. by Dr. Brad DeLong. Retrieved December 21, 2010.

- 'All-Wheel Drive Revolution? New Venture Gear leads a shift in AWD technology'. Ward's AutoWorld. Archived from the original on December 26, 2004. Retrieved January 3, 2006.

- 'GM Drops Its Stake in New Venture Gear'. Ward's AutoWorld. Archived from the original on January 20, 2005. Retrieved January 3, 2006.